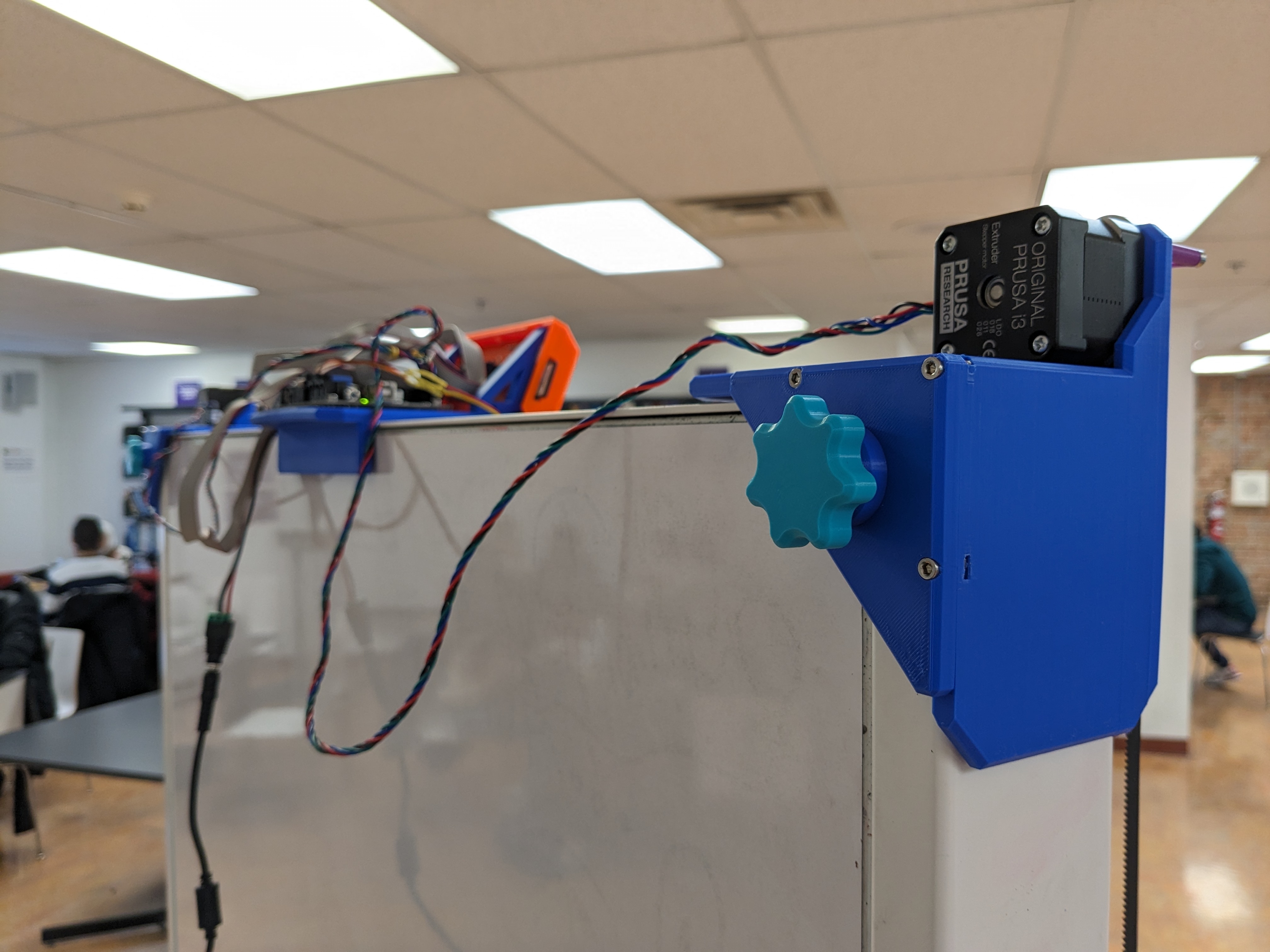

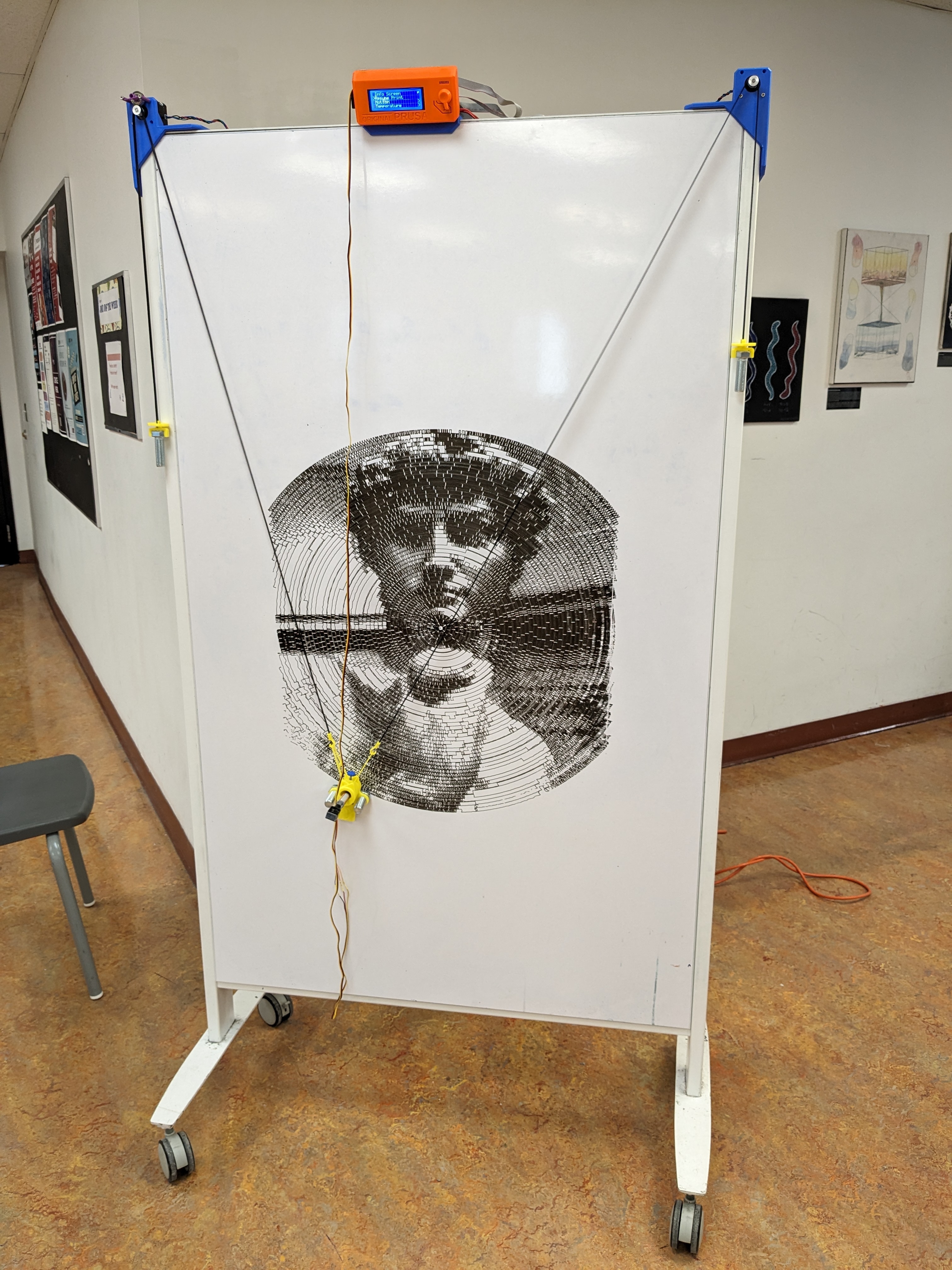

What the what? Did you just turn a 3d printer into a 2d printer? This is amazing! Only a 1d printer would astonish me more!

... Would that be a seismograph?

Im afraid it would just be a thing that makes perfectly straight lines :(

That you couldn't see, since they'd have no thickness, only length

Maybe a printer that adds Morse code on a string.

That's still 2 dimensions.

How do you keep the pen tips vertical position accurate as it pens around without something dragging in the drawings?

I'm not perfectly sure I understand your question, but if you see it in action, this thing is really wobbly. Not much precision there.

I was basically just asking how wobbly it is, haha.

That's really cool!

You’re amazing

I've been thinking of doing just this as well. Though with ender parts or something else left over. Very cool to see someone's actually made it happen.

You should check this post out if you ever go ahead with it: https://www.marginallyclever.com/2021/10/friday-facts-4-how-to-marlin-polargraph/

Oh, I'm definitely stashing that. Thank you.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible