view the rest of the comments

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

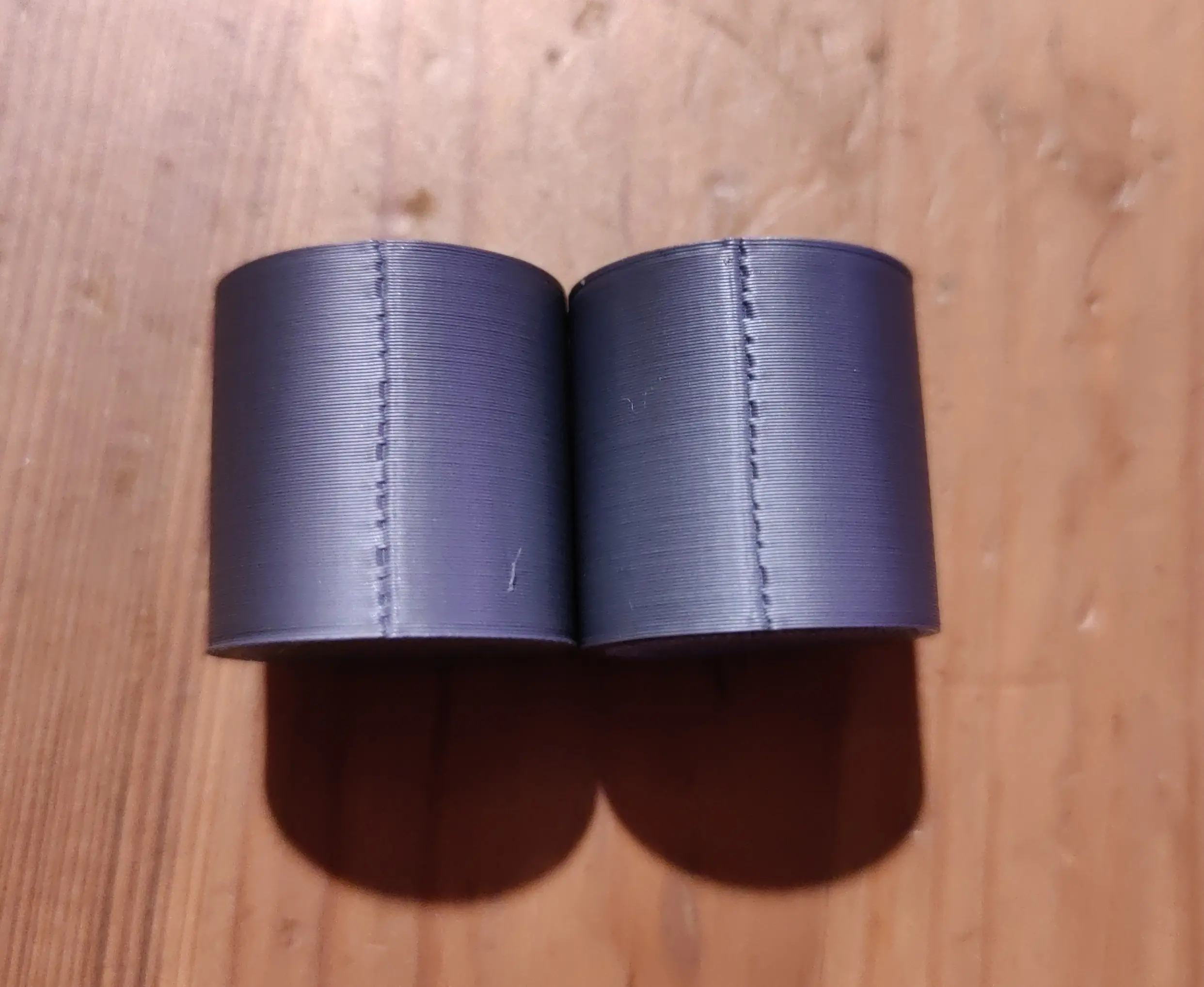

That retract distance seems a bit low to me. My (direct drive) printer is happier around 1mm to 1.5mm. I'm not convinced that has anything to do with your particular problem, though.

Anyhow, to my untrained eye that looks like underextrusion at layer change and/or the perimeter lines not actually hitting each other. Are you sure your pressure advance/linear advance values are correct for that filament?

Also, does Orca Slicer allow you to specify a negative value for the seam gap? If so, that might be worth fooling with to see if it has any impact. That's probably a band-aid, though. I think your issue lies in pressure advance tuning still.

This is the filament I've tuned PA with, and to my best ability this is what Elli's guide suggests is the optimal value 🤷♂️

But I agree, it does actually look like PA is tuned incorrectly and stopping extrusion too soon/starting it too late.

Try without PA, also try another filament

Also try normal brass nozzle and check if your new hotend is not loose

Tried without PA but there was no difference, going to try different filament next.

As I mentioned somewhere else in this post, it seems to relate to the infill. I'm using gyroid, and the seam lines up with the anchor point for the infill.

You can also try without infill 😉

Im throwing many things to try, but not in any particular order