Hey mate, I keep my filament in a dry cabinet at 5ish% humidity, and I've had the same results with two different filaments in there. I even chucked my filament in a food dehydrator at 40C for 12h with no effect. I'm pretty sure the filament is dry!

I love these! Thanks for sharing!

I know esun is quite popular, but I never tried it.

I've generally had the best results with it. Ironically, before the upgrades I had almost no stringing.

I'm using a 0.4mm nozzle. I probably should have mentioned in the OP that I didn't have problems before, but the upgrades have happened in addition to moving to Orcaslicer.

Now I'm worried if I've got my Bowden tube seated in the hotend correctly...

Thanks for the reply mate!

I didn't think to mess with z-hop - I'll give that a go, and I'll do some testing to make sure the Bowden is seated correctly and the wipe on retract is actually happening - thanks!

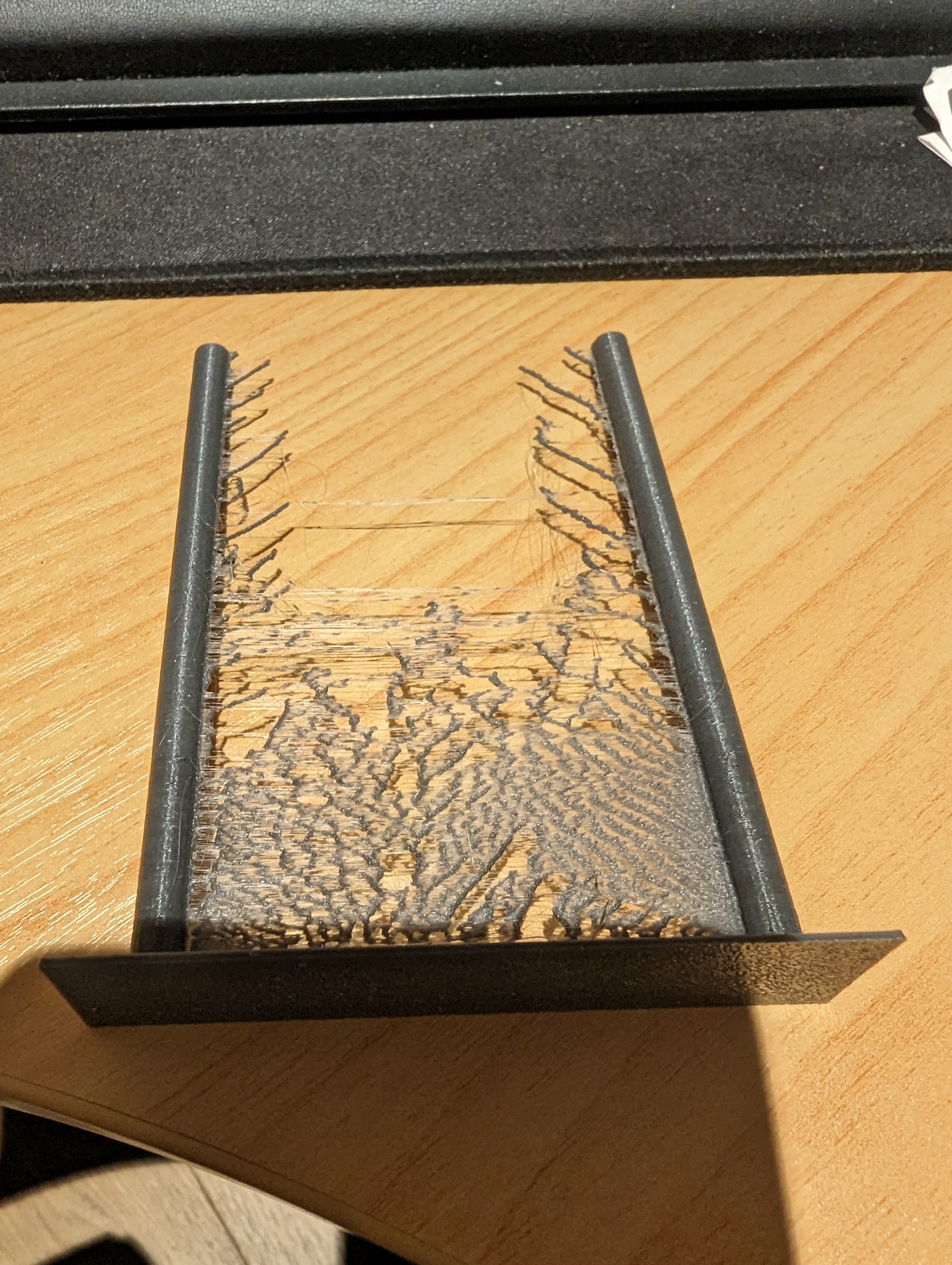

The print in the image is a 'torture test', and just something I had on hand to illustrate the issue. I'm actually not fussed if there is still some stringing at the top, but other detailed prints were getting it pretty bad, including retraction towers.

Hmm yes, good points. I'll have another go with the previous filament.

To be fair, I need to replace the extruder and get a high flow nozzle anyway, which I think will make more difference to the flow rate than running hot.

What temperature are you printing at? When I was using Marlin I ran mine at about 200, and could probably have gone even lower. I also tuned linear advance which made a big difference.

I have found that some esun spools weren't particularly dry when I got them. They sit in my dehumidifier which sits at about 20%, so they get dry eventually.

You can try coasting as well I think.

Yeah lower temps work, but I'm really trying to max out my flow rate so I want to run it as high as possible. Pressure advance really helps reduce ooze, and quality filament is obviously a must.

That site doesn't load for me. I have just been using a retraction tower and running the tuning function from the command line.

In the end it was crap quality filament.

I keep my spools in a dehumidifier which I actually think is too dry. Some of the filament was brittle for the first 6" or so.

Yeah it was rubbish filament. Switched it out for some esun PLA+ and got much better results. I've updated my post, but final settings are:

Pressure Advance - 0.4 Retraction - 3.5mm Retraction speed - 35mm/s

Very happy with the results!

Thanks for your reply, I will give that a go.

After posting I thought to try a different brand of filament. It's currently printing, so we'll see how it goes.

It's all good mate! Thanks for the suggestion. When I first started printing I had that exact issue.