view the rest of the comments

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

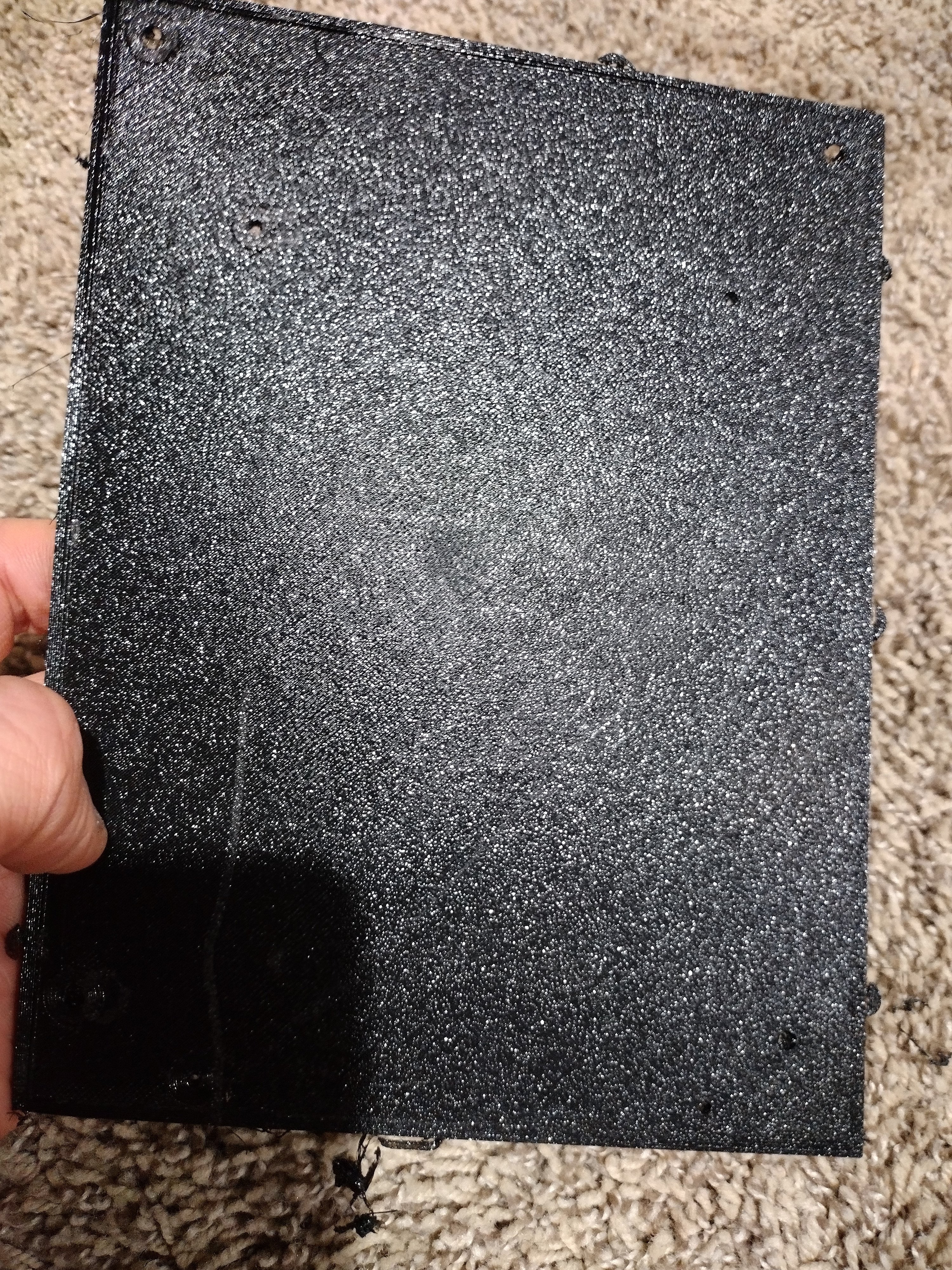

I'd be surprised if it was too cold, but I've heard stranger. This is PETG at 250. I've actually pulled the nozzle and Bowden tube and pushed a very small Allen key through, so it shouldn't be clogged.

Z height is calibrated, and I've calibrated the e-steps for the z axis. I've tried disabling the fade height to see if that was doing something but it didn't seem to make a difference.

I ran through calibrating the extrusion e-steps. It's feeding 100mm when I tell it to do so. I haven't messed with the extrusion multiplier, do you have any information about that?

This is quite toasty, at least for the PETG I print. I'm usually at around 240 for my first layer and 230 or 235 for all subsequent layers.

Have you run a temp tower?

https://ellis3dp.com/Print-Tuning-Guide/articles/extrusion_multiplier.html for more info. In a nutshell, you lower it for oozie filament and increase it for more viscous filament. For PETG I lower it some, but the exact amount varies by filament brand and color.

That said, I don't think this is your issue.

I haven't run a temp tower. I'm not fully convinced that it won't damage itself so I've been trying to think through it before trying another print.

If you are suffering a clog and/or under extrusion issue the worst I've ever seen happen on my printers is the extruder clicking because the e-stepper is trying to step, but can't. It might not be a bad idea to go over all the connectors in that path. When I finished building my Voron one of the factory terminals in the LDO stepper's connector had a terminal that was backed out, causing weird extrusion issues.

The print before this one, the blobbing/shreds were tall enough that one grabbed the BLTouch probe and bent it a little. I was pretty mad about that tbh.

I'll double check my connectors. That's a solid shout actually.

You only calibrate E, calculate for XYZ.

Calculate the rotation distance for the Z, if it doesn't move the correct distance when asked you have a broken part.