view the rest of the comments

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

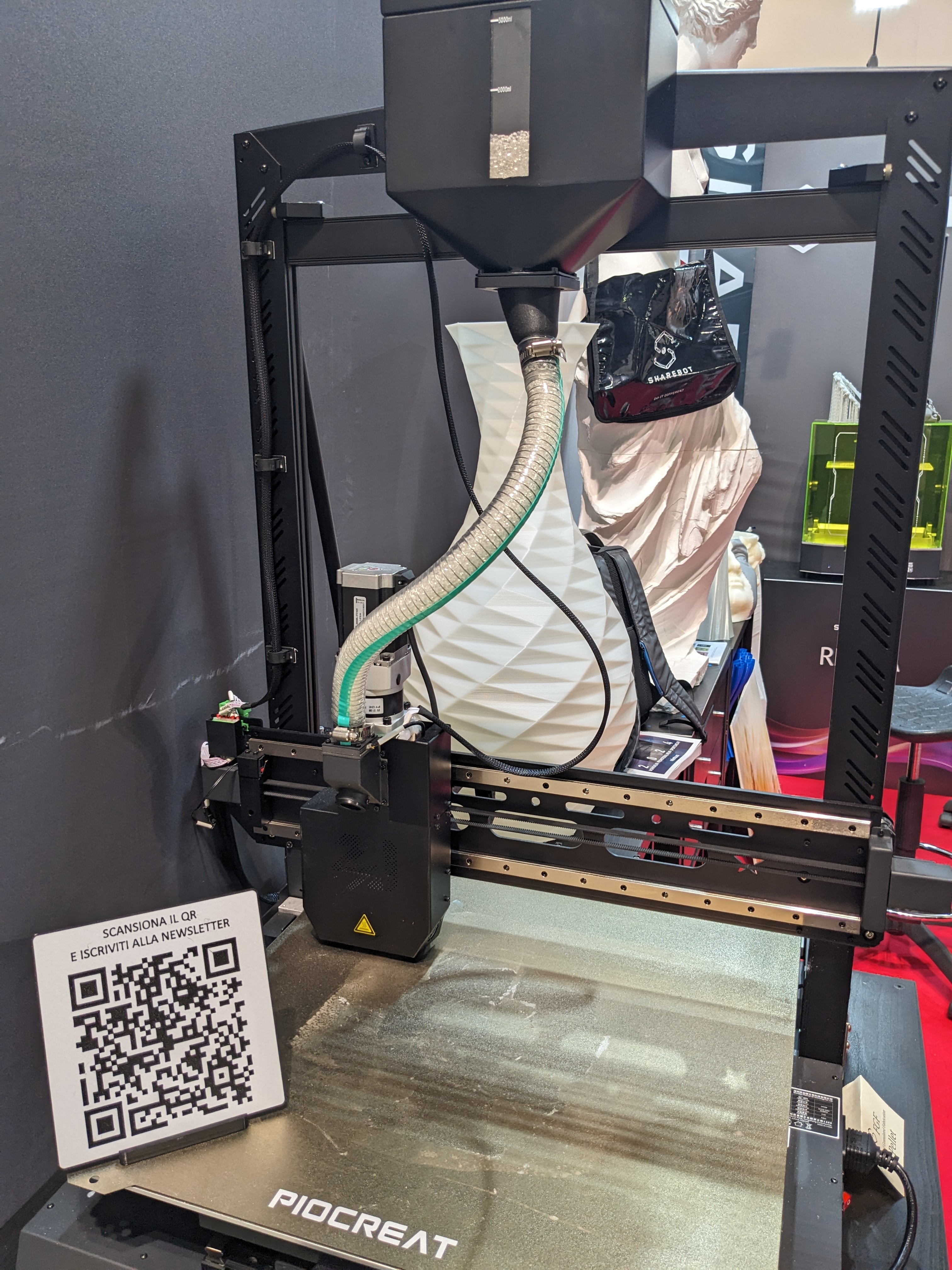

You want to minimize wight and vibration on the printing head. And everything that deals with pellets adds a great deal of both.

In theory you can manage to melt the pellets in a static machine away from the printing head. But you will get a lot of new problems getting it where you need and switching it on and off as needed.

Pellet feeders are not meant for high speed machines. Pellet feeders are for large format machines where the speed comes from the volume of filament they can extrude while printing.

Ok. That is a very compelling use case. I guess over some size they become a non-brainier.