I am all for the news about Mars, as long as it has nothing to do with Husk. If that fucker wants to go, he can take his groupies and go. Well, I would also tune into the news if it turned into a pseudo-Last Recall story and some alien artifact collapsed the exploitive oxygen trade.

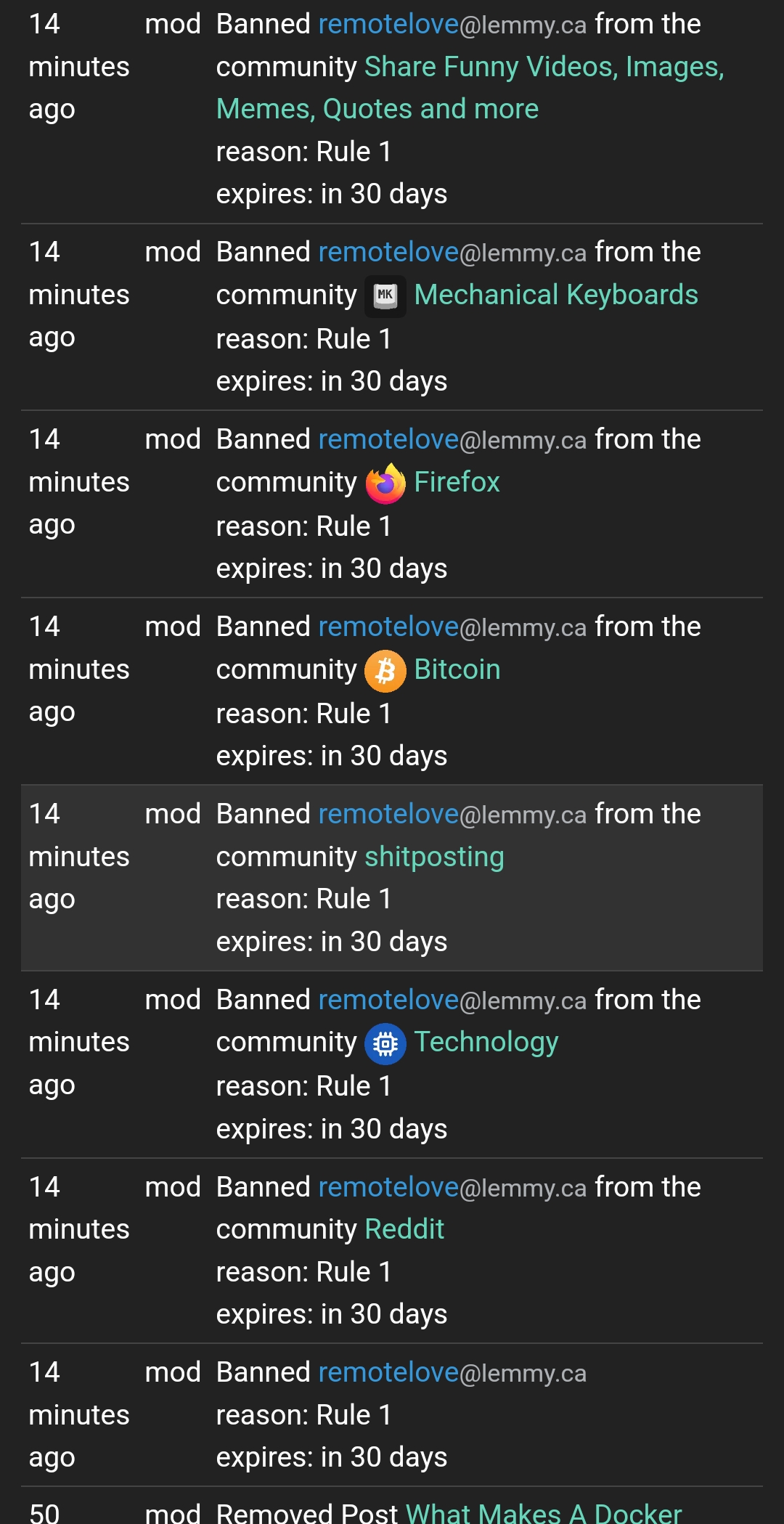

I can still report posts on communities that I wasn't explicitly banned from, which is just super weird. A proper ban prevents reports, at least.

TBH, I don't care about the bans, but the Lemmy behavior is something to take note of for other admins and mods.

It's also super inefficient. Comrade dipshit missed quite a few communities so it seems he can only ban based on communities I have commented in at one time or another.

You would think that the free speech leader of the world could write a better mechanism to erase dissent.

Nah. I didn't delete the post on 196 from that last meme-athon, so that probably chapped Dessi's hide a bit. (My achievement counts double since I am a mod on 196, actually. I just exist to delete dick pics, so it's not a huge role.)

Lulz. I was instance banned by the head comrade himself, so it fits.

Lemmy.ca is where my primary account is at. Those are all actually ml bans on my lemmy.ca account.

Rock on. I was only on ml for a few niche communities and for posting the occasional whataboutisim.

musicproduction was a neat place for a bit, but there are tons of other alternatives.

I do need to post an issue on GitHub though. It seems that every comment I made on ml returned a "Rule 1" error. The devs really need to be aware of that flaw.

Cool! I have been around a while so I know those communities well.

(I hope I wasn't auto banned from those places too...)

Fuck yes! I just saw when I attempted to post to 3D printing.

Lol! I am getting rando-banned as well! I guess the head Nazi doesn't like people associating with you. (This was on 3D printing, of all places. Wut.)

Just report every post you see as Rule 1. That should still be in spirit with the boycott.

AIDS doesn't exist in Russia and is just CIA propaganda.(Someone from ml probably.)